The Road to Faster Fulfillment

Insights from ProMat 2025: How Decoupled Human-Robot Workflows Transform Warehouse Fulfillment Speed

BY ONWARD ROBOTICS | April 3, 2025

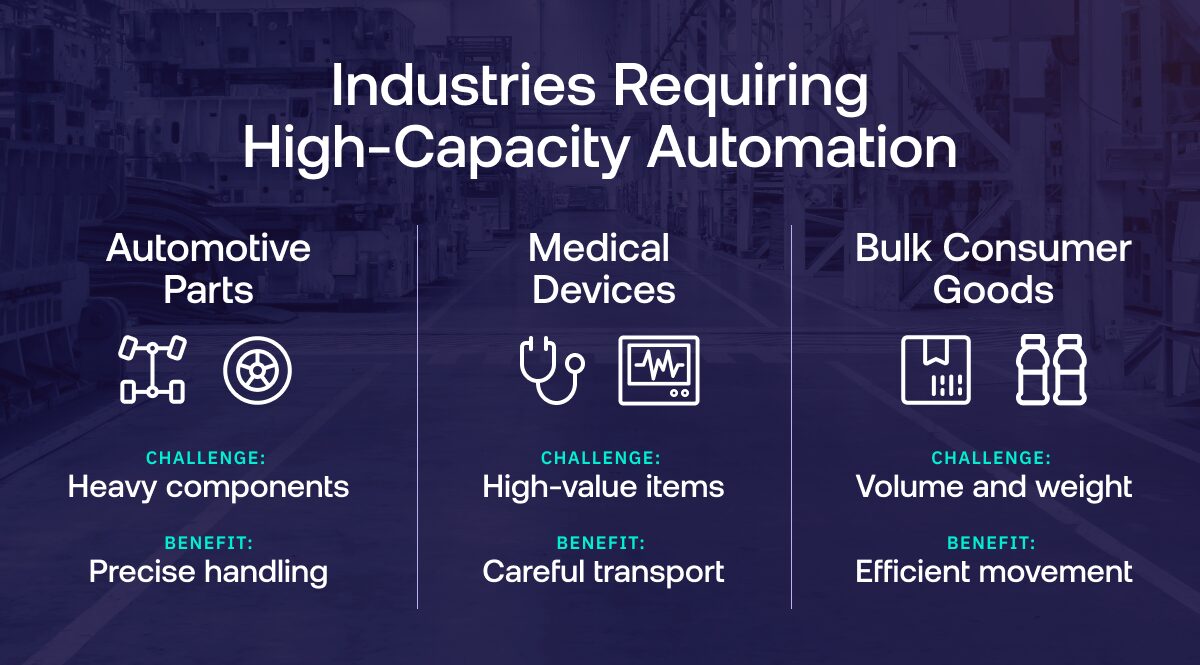

The race for speed and precision in fulfillment has never been more intense. As e-commerce booms and supply chains stretch across the globe, businesses are under relentless pressure to deliver faster, with near-perfect accuracy. From automotive parts to medical devices and everyday essentials like shampoo, consumers expect instant gratification—placing immense demands on warehouse fulfillment and distribution centers.

To stay ahead, companies are reimagining fulfillment with cutting-edge automation, transforming traditional operations into seamless, technology-driven ecosystems designed to meet the urgency of modern commerce.

Redefining Efficiency in Order Fulfillment

Fulfilling orders quickly and accurately is essential for businesses looking to maintain customer satisfaction and optimize supply chain operations. Person-to-goods pick automation has emerged as a leading strategy for improving efficiency by reducing the time human workers spend retrieving and moving inventory. Instead of relying on manual, labor-intensive workflows, companies are adopting hybrid models that blend human oversight with machine precision, enabling unprecedented efficiency.

Moreover, as supply chains face increasing volatility, flexible, infrastructure-free automation systems are becoming a critical asset. Fluctuating demand, seasonal spikes, and the rise of same-day or next-day delivery expectations require solutions that can dynamically adjust to changing conditions. Businesses that fail to optimize fulfillment speed risk falling behind competitors that leverage automation to meet customer demands more effectively.

The future of fulfillment isn’t just about being fast; it’s about being agile, adaptive, and ready for what’s next.

The Need for High-Capacity AMRs

Industries handling large or high-value products—such as automotive parts, medical devices, and bulk consumer goods—face unique challenges in fulfillment. The demand for higher-capacity autonomous mobile robots (AMRs) has grown as businesses look for ways to transport heavier payloads efficiently while maintaining warehouse safety and productivity.

With innovative solutions like Lumabot powered by Pyxis and Meet Me automation, Onward Robotics is at the forefront of this transformation, helping companies achieve the speed and efficiency they need to stay ahead.

Labor Shortages and the Role of Human Robot Collaboration

A growing challenge across industries is the persistent labor shortage affecting supply chain operations. Recruiting and retaining warehouse staff has become increasingly difficult, and businesses must find ways to maintain productivity despite workforce constraints. Human-robot collaboration (HRC) offers a viable solution by combining human decision-making and adaptability with robotic efficiency and precision.

HRC enhances productivity by allowing robots to handle repetitive, physically demanding tasks while human workers focus on strategic and value-added activities such as quality control, customer service, and process optimization. This collaborative approach not only boosts operational efficiency but also improves worker satisfaction by reducing physically strenuous labor and creating a safer workplace.

The Future of Fulfillment is Automated

Automation is transforming the future of order fulfillment, making processes faster, smarter, and more efficient. From robotic picking systems to AI-driven inventory management, businesses are leveraging cutting-edge technology to meet growing consumer demands. Automated fulfillment centers powered by robotics and real-time data analytics are reducing errors, lowering costs, and accelerating delivery times.

As machine learning and computer vision continue to advance, robots are becoming more adaptable, handling a wider variety of products with precision. The future of fulfillment is not just automated—it’s intelligent, scalable, and essential for companies looking to stay ahead in an increasingly competitive market.

How Onward Robotics Supports Faster Fulfillment

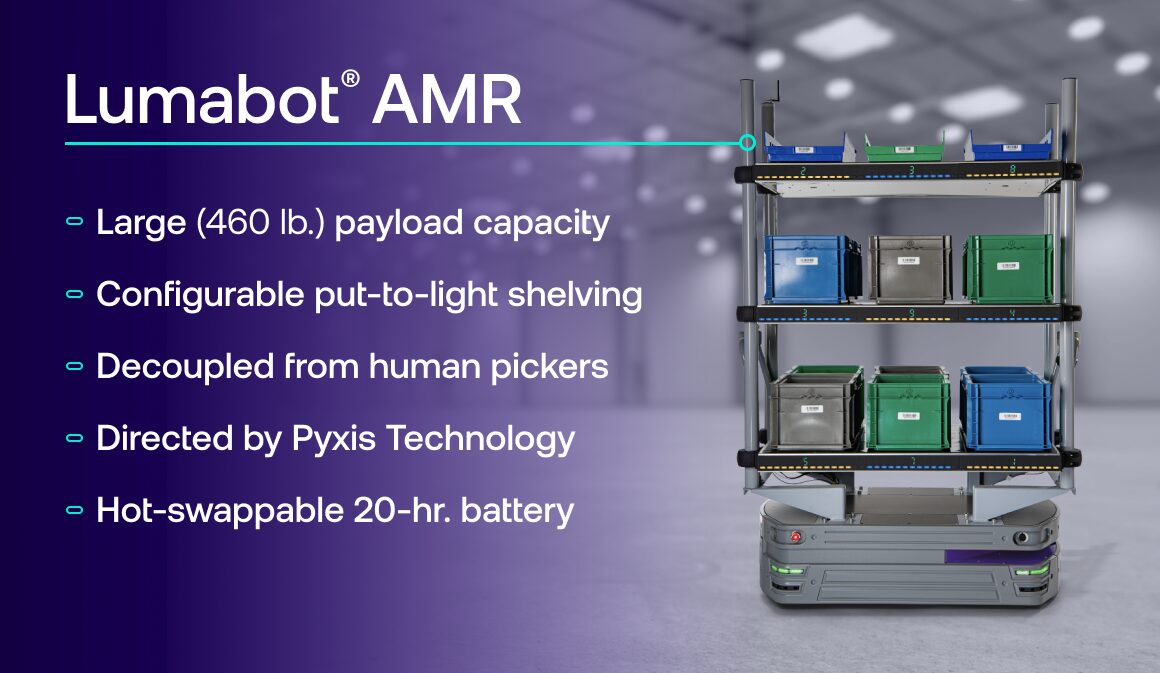

As businesses seek automation solutions that align with their operational needs, Onward Robotics offers cutting-edge technology designed to streamline fulfillment workflows. Onward Robotics’ automation solutions, including its Meet Me system and high-capacity AMR, Lumabot, optimize warehouse efficiency by strategically integrating automation into existing operations. With a 460 lb. capacity and up to five configurable shelves, Lumabot is built to move more, adapt to diverse picking needs, and enhance operational speed and accuracy.

Unlike traditional collaborative robotics that require constant human-robot interaction, Onward Robotics’ approach decouples human and robot workflows, ensuring that employees remain focused on picking and value-added tasks while robots efficiently handle material movement.

This method reduces bottlenecks, enhances throughput, and minimizes downtime—all key factors in achieving faster fulfillment.

By leveraging intelligent robotic solutions, businesses can improve fulfillment speed, enhance worker productivity, and adapt to growing market demands. As supply chain challenges evolve, companies that implement scalable and flexible automation today will be better equipped for long-term success in the competitive logistics and distribution sector.