Unlocking Efficiency: A Beginner’s Guide to Collaborative Fulfillment Robots

Introduction

From warehouse logistics to manufacturing floors, collaborative robots have become an integral part of the modern supply chain as businesses seek to enhance efficiency and streamline operations. In fulfillment, collaborative robots–especially autonomous mobile robots (AMRs)–have emerged as a key part of automation strategies, playing a critical role in helping companies stay agile, reduce labor bottlenecks, and adapt to shifting demand.

In fact, adoption of collaborative robots into order fulfillment processes has surged in recent years, driven by the need for scalable, workforce-friendly automation. But what exactly do collaborative fulfillment robots, or “cobots” entail, and how do they benefit businesses looking to optimize operations?

Table of Contents

Free Resource: The Complete Glossary of Fulfillment Terms

chapter 01

Collaborative Robots 101

How People and Machines Work Side by Side to Boost Efficiency, Safety, and Productivity

Collaborative fulfillment robots, or cobots, refer to the seamless interaction of robots and human employees in shared workspaces, where they perform tasks alongside or in conjunction with one another. Cobots enable a more dynamic and flexible interaction between humans and machines.

The right cobot for your fulfillment operations depends on your business needs, the nature of the work your operation is performing, your existing infrastructure, and your company’s innovation and automation goals. In industries like manufacturing, logistics, and wholesale distribution, cobot applications vary widely based on use cases: some organizations deploy industrial robotic arms for repetitive tasks, while others opt for flexible solutions like autonomous mobile robots (AMRs) that enable more adaptive human-robot collaboration to boost efficiency.

- Pick-and-Place Robotic Arms are stationary cobot systems designed to handle repetitive material handling tasks with high precision, featuring articulated joints that allow them to grasp objects from one location and move them to another. These cobots are commonly used in manufacturing for assembly line tasks, in each-picking for order fulfillment, in packaging operations, and in quality inspection—robotic arms also excel at delicate electronics assembly and small parts handling.

- Autonomous Mobile Robots (AMRs) are collaborative mobile robots that navigate and perform tasks in dynamic environments without the need for fixed infrastructure or direct human control. While pick-and-place arms excel at precise manipulation tasks within a fixed workspace, AMRs provide flexibility for autonomous material movement across larger areas, with both types designed to work safely and collaboratively alongside human workers without traditional safety barriers. In fulfillment operations, AMRs work collaboratively alongside people as part of the order-picking workflow, enabling companies to pick more orders faster and more accurately—improving overall throughput in the order fulfillment process.

chapter 02

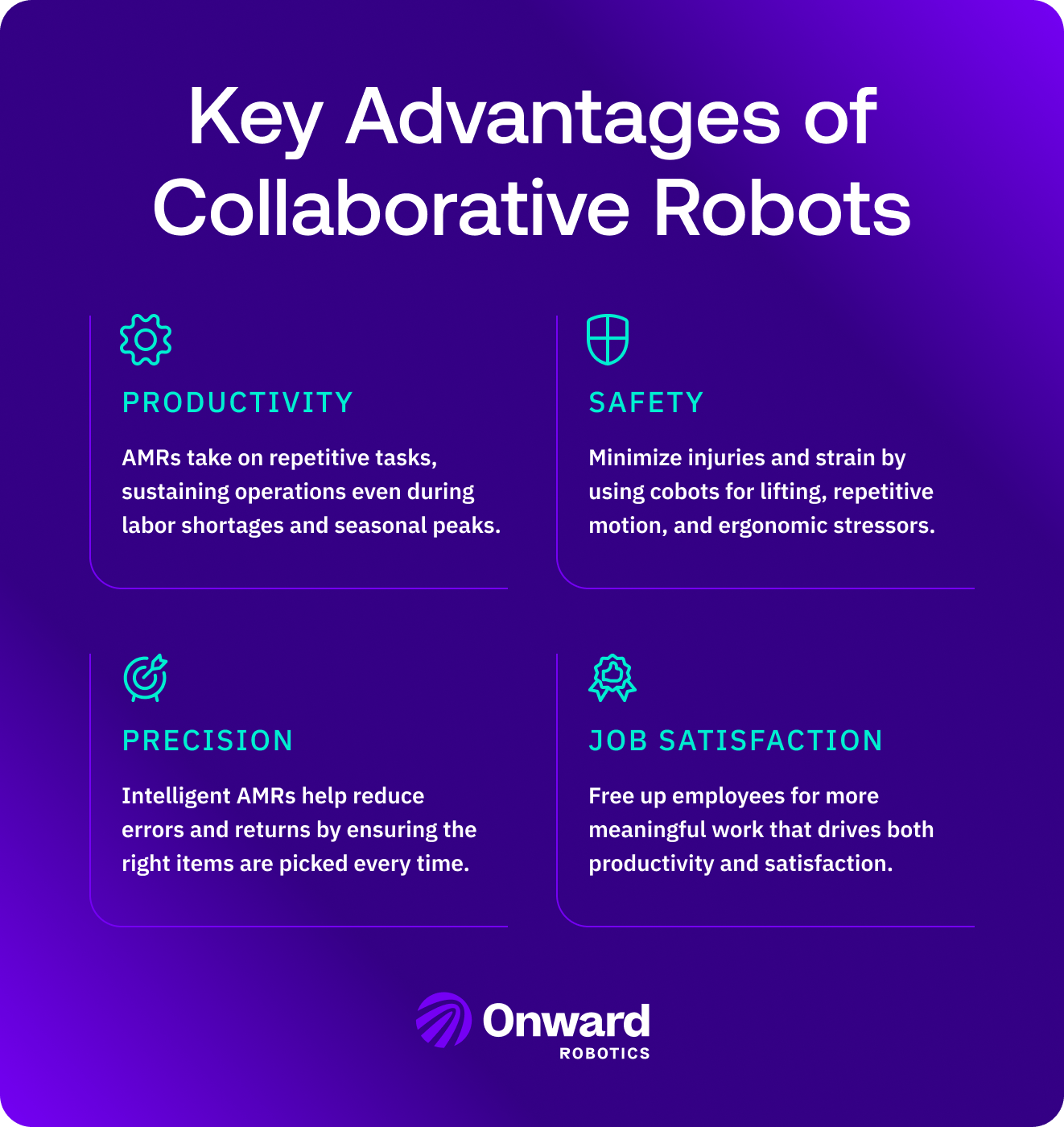

Top Benefits of Collaborative Fulfillment Robots

Advantages of Integrating Collaborative Robots into Your Fulfillment Workflows

HRC offers numerous advantages, particularly in industries where efficiency, safety, and precision are crucial. Some of the key benefits include:

Increased Productivity Despite Labor Challenges

Manufacturing, distribution, and fulfillment centers across the country are struggling to recruit and retain workers. Labor-intensive roles, seasonal spikes, and physically demanding tasks make staffing a constant challenge. By leveraging intelligent collaborative robotic systems, companies can unlock faster, more efficient fulfillment operations amidst labor shortages.

Improved Warehouse Safety

In 2023, the U.S. Bureau of Labor Statistics reported 2.6 million nonfatal workplace injuries, with warehousing and transportation seeing 4.5 cases per 100 full-time workers—many due to overexertion from lifting, repetitive motion, and poor ergonomics. Cobots help reduce these risks by handling the physically demanding tasks and creating safer, more efficient workplaces for people.

Enhanced Accuracy and Quality

Fulfillment AMRs are designed to minimize human error, ensuring that the pickers select the right items for each order. This enhanced accuracy not only reduces costly mistakes but also improves inventory management, helping businesses maintain trust with customers and reduce returns.

Improved Labor Efficiency

By removing non-productive movement from your operation. By eliminating the time pickers spend walking completed carts to drop-off or retrieving new ones, teams can stay focused on high-value tasks like picking to boost overall throughput.

chapter 03

Real-World Applications of Collaborative AMRs

How AMRs Enhance Efficiency, Accuracy, and Foster Human-Robot Collaboration in Fullfillment Workflows Across Industries

Collaborative fulfillment AMRs enable companies across diverse industries with unique challenges to unlock powerful operational benefits: streamlining processes, enhancing accuracy, and improving overall workflow performance.

Retail & E-Commerce Fulfillment

Key Challenge: Managing omni-channel fulfillment with rising consumer expectations and surging order volumes

In retail and e-commerce fulfillment centers, fulfillment AMRs work alongside associates, boosting picking productivity and increasing order accuracy. AMRs help to accelerate order fulfillment times and enable retailers to keep up with consumer expectations for next day delivery–particularly during busy peak holiday seasons.

Third-Party Logistics (3PL)

Key Challenge: Meeting complex SLAs and customer requirements amidst labor shortages, space constraints, and rising costs

As SLAs become shorter and more complex, third-party logistics providers must keep up while contending with constrained and costly warehouse space and labor. For 3PLs handling heavier or bulky products, cobots like Onward Robotics’ Lumabot AMR have a 450 lb. payload capacity and configurable shelving to accommodate variable SKU sizes, so every customer order gets out the door faster.

Healthcare & Medical Devices

Key Challenge: Reduce picking errors, increase speed for extremely high-priority order fulfillment

In the healthcare and medical device industries, accuracy isn’t just about operational efficiency—it’s about patient safety. Within fulfillment centers, AMRs support human workers by handling the most time-consuming and error-prone parts of the picking process. Fulfillment AMRs optimize picking workflows and turn unproductive time into productive output—unlocking new levels of efficiency without disrupting existing operations.

Industrial Warehousing & Manufacturing

Key Challenge: Optimizing fulfillment, kitting, and parts replenishment while managing high labor costs and turnover

Industrial warehouses and manufacturing facilities rely on predictable, accurate, and reliable movement of materials–they need their internal processes to run consistently and efficiently. Collaborative fulfillment robots in the industrial space increase the accuracy of orders picked and move product more efficiently, and can contribute to lean manufacturing process efforts. AMR cobots support higher capacity payloads (up to 450 lbs) and reduce costly downtime, so industrial suppliers can fulfill heavier, bulkier, or more complex orders, faster.

Wholesale Distribution

Key Challenge: Maintaining flexibility and scalability while dealing with increased demand

Modern wholesale distributors turn to collaborative AMRs to stay flexible amidst challenges with unpredictable demand, supply chain disruptions, and workplace safety. AMRs help wholesale distributors meet aggressive delivery commitments while maintaining the speed and accuracy that both retail partners and end consumers demand.

chapter 04

With Added Intelligence, Fulfillment Cobots Optimize Operations

How AI Is Elevating Cobot Adaptability and Awareness

As cobot technology advances, artificial intelligence (AI) and machine learning are playing a growing role in enhancing how collaborative robots perceive and respond to their environments. Modern collaborative robots are increasingly capable of understanding context, adapting to variable workflows, and even learning from human behavior. This means they’re not only performing programmed tasks but also continuously optimizing how they support human workers.

From dynamic path planning to real-time task reprioritization, intelligent systems like fulfillment AMRs make human-robot collaboration smoother and more effective. Orchestration technologies like Onward Robotics’ Pyxis software exemplify this advancement—unlocking new levels of productivity that were previously out of reach with static automation.

chapter 05

Key Considerations for Implementation

What to Know Before You Deploy Collaborative Fulfillment Robots

Implementing collaborative robotics isn’t just a technical upgrade—it’s a strategic transformation. Success depends on more than just installing new machines: it requires careful alignment with your operational goals, thoughtful change management, and a workplace culture that embraces innovation.

Clear safety protocols, hands-on training, and guidance for employees on those workflows designed for human-robot interaction are essential. Just as important is choosing cobot technology that enhances your existing processes instead of disrupting them. By focusing on flexibility, usability, and workforce readiness, businesses can accelerate adoption and unlock the full value of collaborative automation—without the growing pains.

chapter 06

Looking Ahead With Collaborative Robots

Preparing for What’s Next: Why Intelligent Collaboration Is Key to Long-Term Success

Cutting-edge, collaborative solutions like Onward Robotics’ Meet Me automation technology take a smarter, more flexible, and more efficient approach. Meet Me automation decouples human and robot workflows in the order fulfillment process: robots handle material movement and “meet” pickers at the next best pick location, allowing human workers to focus on the higher-value task of picking. This results in a more streamlined process, with picking productivity increasing by 15–25% compared to traditional models.

By reducing bottlenecks, optimizing task allocation, and minimizing downtime, this decoupled model helps both humans and robots perform at their best. Most importantly, it allows businesses to integrate automation with minimal changes to existing brownfield fulfillment operations—making it faster and easier to scale.

chapter 07

Conclusion

Future-Proofing Your Operations with the Right Collaborative Strategy

Collaborative robotics is no longer a futuristic concept—it’s a critical driver of productivity, safety, and operational resilience in warehouses, distribution centers, and fulfillment centers across industries. While various models of collaborative fulfillment robots exist, innovative solutions like Onward Robotics’ Meet Me Fulfillment Solution offer a smarter, more scalable approach by strategically separating human and robotic workflows.

This decoupled model empowers each part of the workforce—human and robotic—to operate at peak performance, reducing inefficiencies and minimizing risk. As industries face mounting pressure to adapt quickly and sustainably, selecting the right collaboration strategy is key. Whether through direct interaction or intelligent decoupling, businesses that embrace flexible, human-centric automation will be best positioned to lead in the era of smart fulfillment.

Free Resource

Download our Ultimate Guide to Warehouse Automation: Complete Glossary of Fulfillment Terms for a quick breakdown of the concepts you need to know when exploring order fulfillment automation.