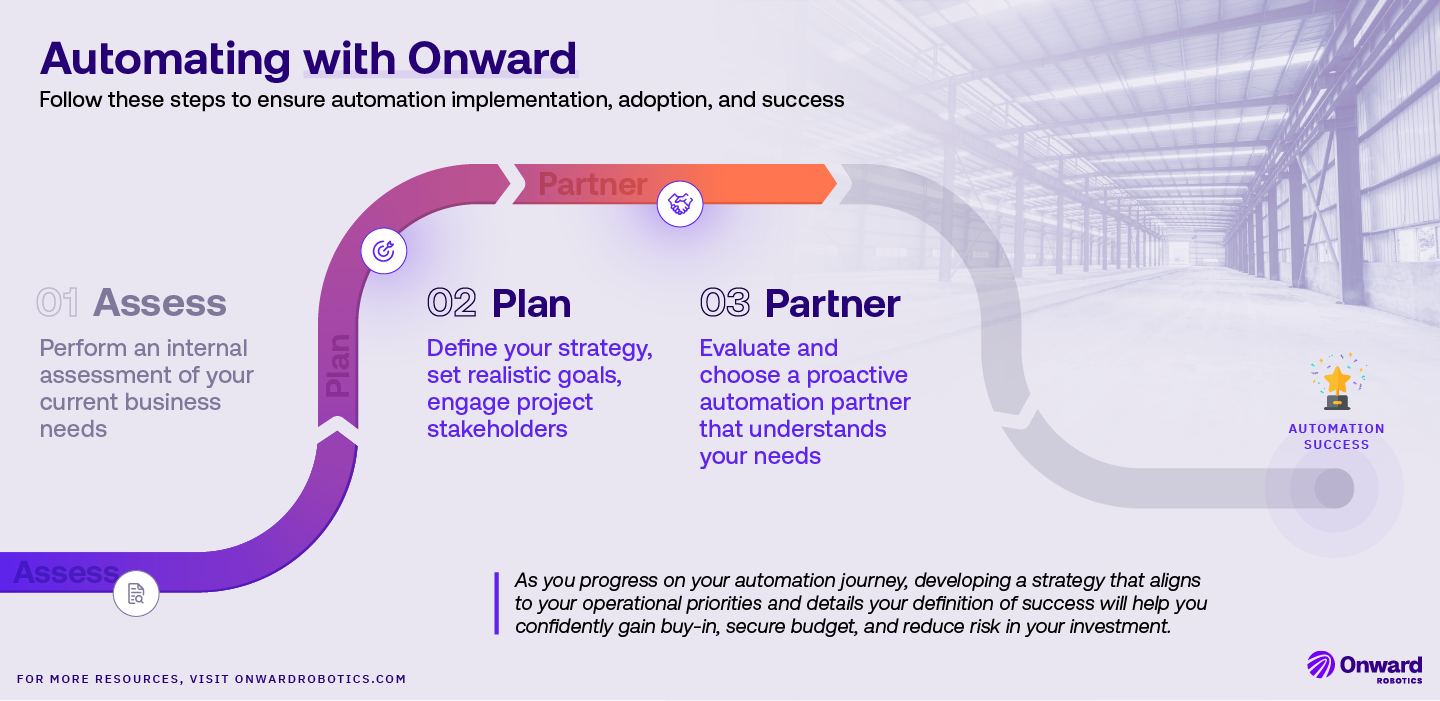

Plan and Partner: Key Steps In Your Warehouse Automation Strategy

JUNE 3, 2024

Armed with a thorough assessment of your warehouse operations, manual processes, inventory management gaps, and current warehouse management systems (WMS), developing an automation strategy that aligns with your operational priorities is vital to securing budget, gaining key stakeholder buy-in, and defining success. Planning prepares you for automation technology selection, vendor evaluation, and automated warehouse system requirements, providing a north star to get you where you want to be–so your automation partner can help get you there.

Step 2: Establish Goals That Align With Your Operational Strategy and Warehouse Automation Plan

Applying the assessment of your current operations, inventory control workflows, material handling processes, and digital automation opportunities, you can craft a well-informed automation strategy: clearly outlining your objectives, goals, and deliverables to achieve automation success. Harnessing insights from your internal assessment and data gathering, you can build an informed roadmap to transition from manual to automated processes to automated systems that improve warehouse efficiency and reduce operational bottlenecks. A comprehensive and collaborative strategic approach to planning will be critical in reducing risk and increasing buy-in for investment.

Define Clear Automation Goals and Objectives for Warehouse Efficiency

In the early stages of planning for automation in your warehouse, it’s important to consider not only your short-term goals for the current project but also to account for the future state of your operations.

Detail your short-term goals: Evaluate your assessment data and operational priorities inventory tracking accuracy, and upcoming peak periods for the coming year. Highlight any known gaps and unknown variables that may disrupt your automation adoption plan.

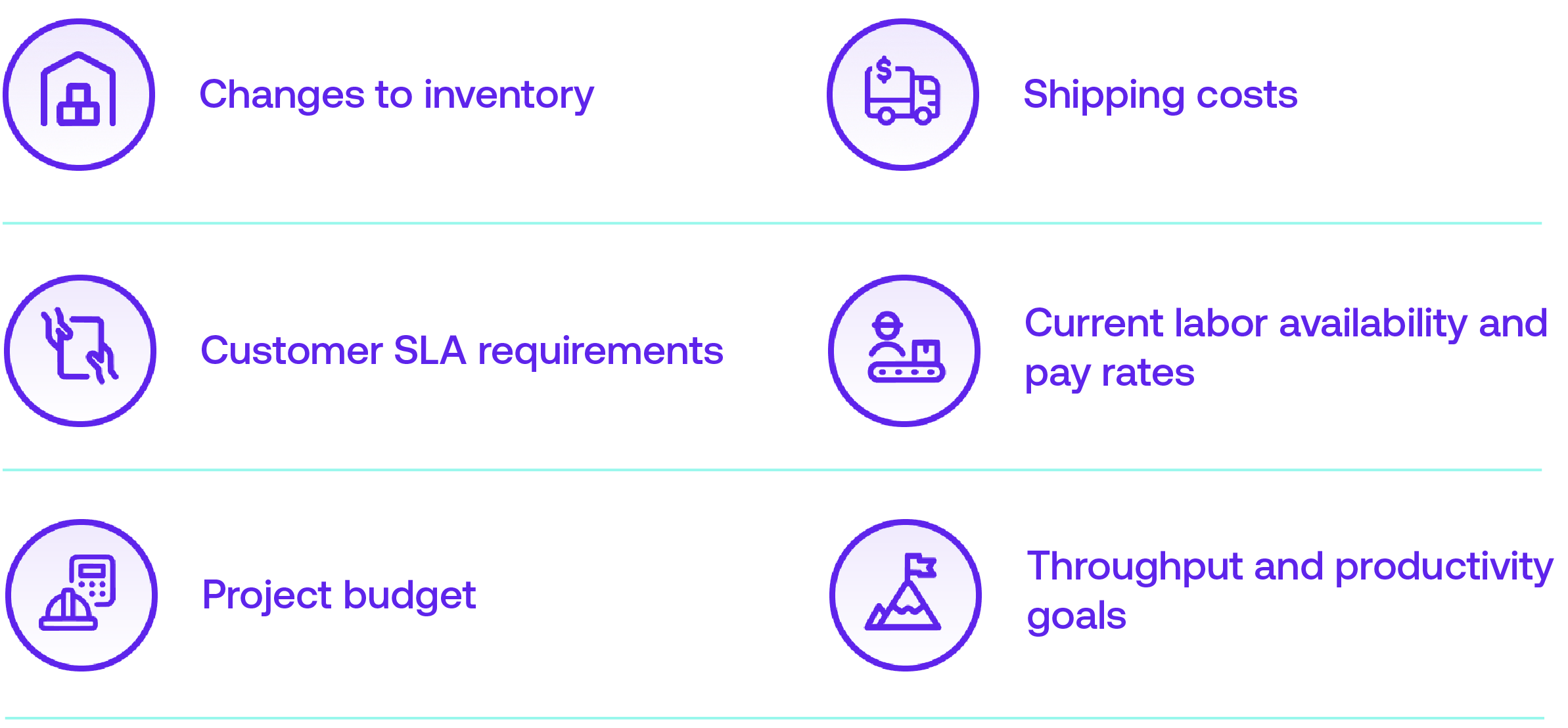

Consider your broader operational goals and how automation will have an impact, documenting key metrics like:

Future-proof your warehouse automation plan for scalability

With ongoing and inevitable changes to your business, building in the flexibility to adapt and scale as needed is a “must-have,” not a “nice-to-have.” Your operations will change, and you need warehouse automation systems—whether AMRs, automated guided vehicles (AGVs), conveyor systems, or automated storage solutions—that can evolve with your warehouse layout and long-term strategy. Focusing exclusively on near-term planning puts you at risk for frequent and time-consuming updates, reconfiguration, or replacements that will be more costly in the long run. Consider not only your roadmap but also where your customers and your competition are going, so you can stay ahead of the curve.

Align your automation strategy to operational priorities and core warehouse processes

Using the pain points and metrics gathered in your initial assessment, focus on the key processes you want to automate and the operational outcomes you want to influence. These key processes include: order processing, replenishment, putaway, inventory counting, material transport, and fulfillment tasks handled by warehouse workers and operators. Optimize your plan by considering what processes can truly be automated versus those that require a human touch.

Be specific and demonstrate impact: identify key metrics and align them to your business plan. These will be initial targets based on your operational priorities that will be underpinned by specific ROI models once you choose an automation partner. Examples include:

- Enhancing warehouse efficiency

- Increasing automated storage throughput

- Reducing warehouse process cycle times

- Increasing accuracy and inventory control

- Reducing overhead costs

- Increasing productivity

- Adding flexibility to adapt to fluctuating demand

- Reducing dependency on labor

Reconcile your warehouse automation plan with cross-functional stakeholder needs

Collaborate with operational experts within your business and your industry to understand challenges, best practices, and success strategies. Your team of experts will help you identify risks related to IT integrations, WMS connectivity, network coverage for mobile robots, and digital automation governance. These risks you may not have considered provide valuable viewpoints on your plan, and strengthen your voice for ongoing investment.

Go beyond the warehouse: implementing or scaling automation requires resources beyond your operational team. This includes HR, IT, Finance, Operations, and even supply chain leaders who need visibility into how automation improves upstream and downstream workflows. Consider the near- and long-term benefits of aligning with key stakeholders across your organization.

It can be helpful to socialize your plan with:

01. Human Resources

What training/upskilling will be required for the new technology?

Are resources available for a dedicated project manager?

Do our existing employees have the skills needed to work alongside robots?

Will additional FTEs be required?

02. Information Technology

Will integration with other systems and software (ERP, WMS) be required?

Can your existing infrastructure support mobile automation?

Does someone in IT need to sign off on any new projects within your organization?

If so, how does this project fit into their schedule for deployment?

Ready to Put Your Plan Into Action?

By assessing your operations and creating a thorough plan, you have identified process candidates for automation, narrowing the solutions to evaluate. For many, the next step may feel daunting: with various automation solutions to choose from and championing a vital strategic investment to improve efficiency, reduce cost, and streamline your operations.

Step 3: Choose a Warehouse Automation Partner (Not Just a Vendor)

When exploring mobile automation solutions, identify vendors based on how well they align to your plan, your logistics warehouse automation needs, and the level of partnership required for long-term success. Mobile warehouse automation continues to grow with innovative technology to transform manual processes, but this also means more options.

Identifying the right technology for your warehouses processes

Different automation technologies (autonomous mobile robots, autonomous guided vehicles, conveyor systems, or robotic arms or automated storage systems) serve different functions within a warehouse, so it’s important to identify which technology properly fits the processes you are looking to automate. Be clear on what you’re moving, how often, and how it connects to other systems like your warehouse management system (WMS). Consider material and container dimensions, weight, travel paths, warehouse layout, throughput, and expected ROI windows.

Conduct Comprehensive automation vendor and technology evaluation

After researching which vendors deliver automated warehouse systems in environments similar to yours., you will conduct discovery calls with some vendors, and then you’ll ask a short list of those vendors to submit a request for proposal (RFP). In your RFP, request things like product demonstrations, ask for examples of existing users with similar operational challenges, and ask the vendor to document evidence of successful implementations. Other things to ask are how technology integrates with your existing WMS, ERP, and inventory management tools.

Ask the tough questions. As you have vendor conversations and get RFP responses, pay attention to how much time each vendor has spent understanding your requirements.

Questions to ask yourself from vendor responses:

- Are they asking detailed questions?

- Are the conversations focused more on the vendor’s technology or how it will actually help my business?

- Can they demonstrate the impact of their automation in a real-world scenario?

- Are they staffed to support me in the short and long term?

- Will I have a dedicated team helping me every step of the way, or is it a plug-and-play solution? Will I have a dedicated team helping me every step of the way, or is it a plug-and-play solution?

Looking beyond technology to assess fit, support, and long-term value

Review your top list of partners and evaluate how well they deliver on your plan, keeping in mind your target objectives and metrics. As you shorten your shortlist, continue to ask detailed questions about each company’s processes and assess whether they fit your business’s operating plan and needs.

Ask your vendors:

- Can you work within my warehouse’s existing infrastructure?

- Will the solution deliver ROI within my targeted time frame?

- How will the automation project be managed?

- What performance data will you provide?

- Will issues be addressed proactively or reactively?

- How do you support ongoing optimization and inventory tracking?

- What data visibility do your robotics and automation tools provide?

- How does your solution improve long-term warehouse efficiency?

Selecting a Warehouse Automation Partner vs. Vendor

A partner applies industry expertise, understands your warehouse operators and managers, and proactively contributes to continuous improvement. They help identify new automation opportunities, improve operational efficiency, and scale automation across your network.

A few key characteristics can help you easily spot the difference:

Working with a vendor

- Transactional, not strategic: A “vendor” goes as far as supplying and perhaps supporting robots and automation software to meet the requirements of the purchase agreement. Typically, a vendor will not extend past the specific process the mobile automation solution was designed for, let alone the broader operational goals or strategy of the client.

- You drive the definition of success: Meeting your goals and KPIs for automation are typically not a shared priority for a vendor. The sale, implementation and possible usage of the automation meets a vendor’s requirements.

- Set it and forget it: Vendor-only relationships typically take a more reactionary approach, waiting for you to reach out if and when there is an issue. These vendors are not proactively looking to optimize your automation solution past the initial deployment or to continue to help you grow.

Working with a partner

- Apply their industry expertise to your individual operation: A partner is knowledgeable not just about the industry and its own technology, but your specific operations, challenges, and goals. A true automation partner takes the time to design a solution tailored to your operational goals. They provide a realistic and achievable automation solution that combines innovative technology with the human support and ingenuity to take your operations to the next level.

- Client first, where success is truly shared: Constantly keeping your plan in mind, a partner proactively collaborates with you throughout the entire automation journey. Whether identifying the right process to automate, suggesting new opportunities, or supporting your team with onboarding and adoption, a partner works alongside you beyond implementation so you can succeed and scale.

- Continuous improvement is the name of the game: An automation partner constantly evaluates and measures the impact of the solution, ensuring that not only is it meeting your existing operational needs, but identifying opportunities to enhance existing automation, accelerate results, and give you a competitive edge.

Activating Automation in Your Warehouse

Once you have selected a partner, the next step is implementing your automation plan. This includes detailed warehouse layout design, technology integration, material flow mapping, and inventory control setup. In our next blog , we will review the design and implementation of your automation strategy: what to expect, how to reduce risk, and ways to quickly achieve ROI and expand automation to bring value across your network.

Onward Robotics is a full-service robotic automation partner, providing the latest in mobile robotic technology and working with you and your team to bring technology and people together for continuous and fast fulfillment. Check out our Meet Me® solution, and contact us today to learn how we can help move your fulfillment onward: onwardrobotics.com/contact